What are Helical Piles?

Also called screw piles, they serve as piles for deep foundations. In soft soils, they transfer a structural load further down to stronger and less compressible materials. Helical piles are screwed into the ground to support new structures or to underpin existing structures that have settled, and can be used in some applications that call for a driven pile, drilled pier, or minipile.

Screw piles are celebrated for their performance in situations where deep foundations are needed or where construction is required close to other structures. They tend to be the most cost effective and practical option while maintaining minimal environmental impact.

Looking to find out the cost of helical piles for your project?

Helical Piles Installation

Square Shaft

Consists of solid square shafts, ranging from 1.5″ to 2″. The piles are typically used for ultimate loads between 100 and 650 kN (25-150 kips) but have been tested to loads in excess of 900 kN (200 kips) in unique situations.

Square shaft products are generally used in small to moderate loading applications, and they provide excellent tension resistance. Square shaft piles are able to penetrate dense and cobble-rich soil when compared to their helical pipe pile equivalents, but they have lower resistance to buckling and negligible lateral load resistance.

Small-Diameter Pipe

Small-diameter pile piles consist of pipe sections ranging from 2 7/8″ to 5.5″ in diameter, with wall thicknesses ranging from 0.203″ to 0.375″ depending on the application and loading. These piles can withstand similar loads to the square shaft pile (100-650 kN, 25-150 kips), but they provide superior buckling resistance and lateral load resistance. Small-diameter pipe helical piles penetrate well into sand and clay, but can be difficult to install in cobble-rich soil.

Square Shaft / Pipe Combo

These piles combine some of the benefits of square shaft and small diameter pipe helical piles. The pile starts with a square shaft and transitions to small diameter pipe. Where depths and soils allow, this pile type provides the excellent penetration of the square shaft piles in addition to the lateral and buckling resistance of the pipe piles.

Large-Diameter Pipe

These piles are the newest emerging product and have gained significant popularity over the last ten years. They consist of pipe shafts ranging from 7″ to 30″ or greater. These piles require large equipment to install and can withstand loads in excess of 2500 kN (560 kips).

Suitability For Low Headroom & Other Limited-Access Areas.

Helical piles can be fabricated and installed in modular systems to accommodate space restrictions and low headroom.

Wide Range Of Allowable Loads

With four types of helical piles to choose from, there are efficient options for small loads of 100 kN (25 kips) up to large loads of 2500 kN (560 kips) or more.

Adaptable To Different Installations Angles

Can be placed at an angle in order to avoid interfering with structures overhead. They can even be installed horizontally for earth retaining projects.

Removable & Reusable

Can be placed at an angle in order to avoid interfering with structures overhead. They can even be installed horizontally for earth retaining projects.

Lower Cost Than Driven Or Drilled Piles.

Because screw piles are simpler and faster to install there are cost savings for labour and equipment.

Ease & Speed Of Installation

Can usually be installed by two people using conventional equipment.

Little Or No Dependence On Weather

Can be installed in almost any weather condition.

Minimal Disruptions

Can be installed with much less noise and vibration than conventionally driven piles.

Little Or No Earthwork & Spoil Material

Helical piles displace very little soil, which is a particular advantage at contaminated sites. There is little or no requirement for removal of excess soil.

Applied Load

The loads that the structure will apply to the pile it connects to. These loads include the dead load, live load, lateral loads, and seismic loading that the pile is being used to resist.

Soil Parameters

Soil strength is reviewed to make sure that it can withstand the load applied by the pile and helix plates.

Pile Capacity

The amount of load that a pile can resist. The pile shaft and connection are selected to resist the applied load. The helix plates are designed based on soil information to ensure that they are the right size.

Termination brackets transfer the load to the pile at the head. The termination bracket is connected to the foundation, typically by attaching it to or casting it into a concrete foundation, or directly to a steel grillage structure.

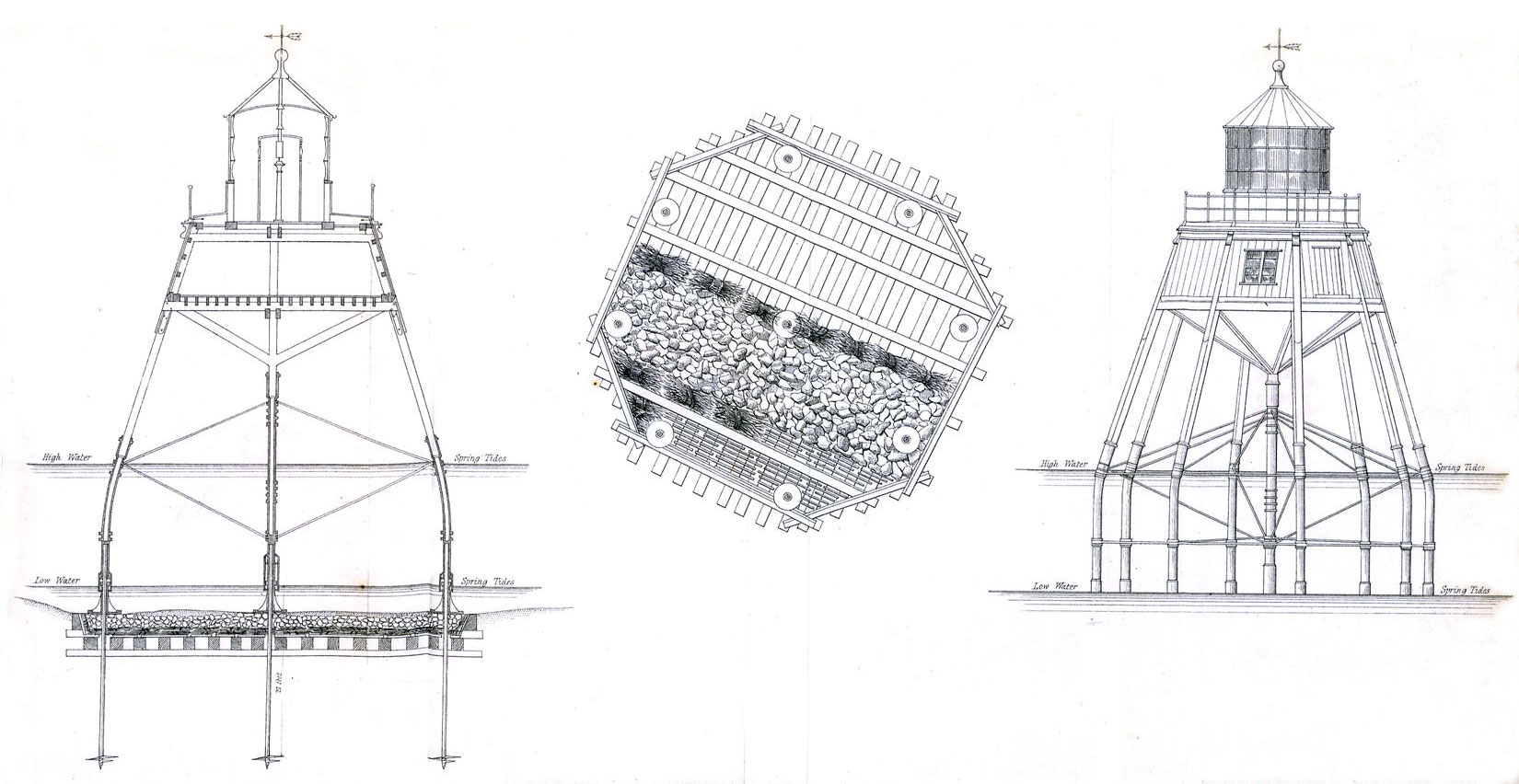

In the nineteenth century, helical piles were the most prominent deep foundation technology. They received UK patents in 1833 and 1847 and US patents in 1845.

Typical early screw piles contained either a 5″ diameter cast iron shaft or 8″ timber shaft with helix plates that were 2.5′ to 4′ in diameter.

Throughout the late 1850s to the 1870s, over 50 structures were built on helical piles, predominantly lighthouse foundations, tiebacks, moorings, ocean front piers, breakwaters, and railway trestles.

By the late 1800s, the technology had spread from England to other parts of the world, including the remainder of Europe, the US, Japan, Australia, and India.

At that time, installation was usually powered by hand or by oxen. Toward the late 1800s, some steam power installations were completed.

The early 1900s to the 1950s saw the rise of other deep foundation systems, including driven piles. The use of helical piles declined as other pile types advanced technologically.

From the 1950s onward, advances in equipment and hydraulics, as well as the need for alternative foundation options, have meant that helical piles are one of the fastest growing deep foundation technologies.